Beginners and advanced swimmers rarely use swimming caps – especially in combination with swimming goggles. The major reasons are the low comfort and the tendency of the goggles to slide of. The aim of the project ClipCap was to solve these issues by giving the swimming cap more functionality and practicability. Additionally, the design of the swimming goggles should match with the one of the swimming cap.

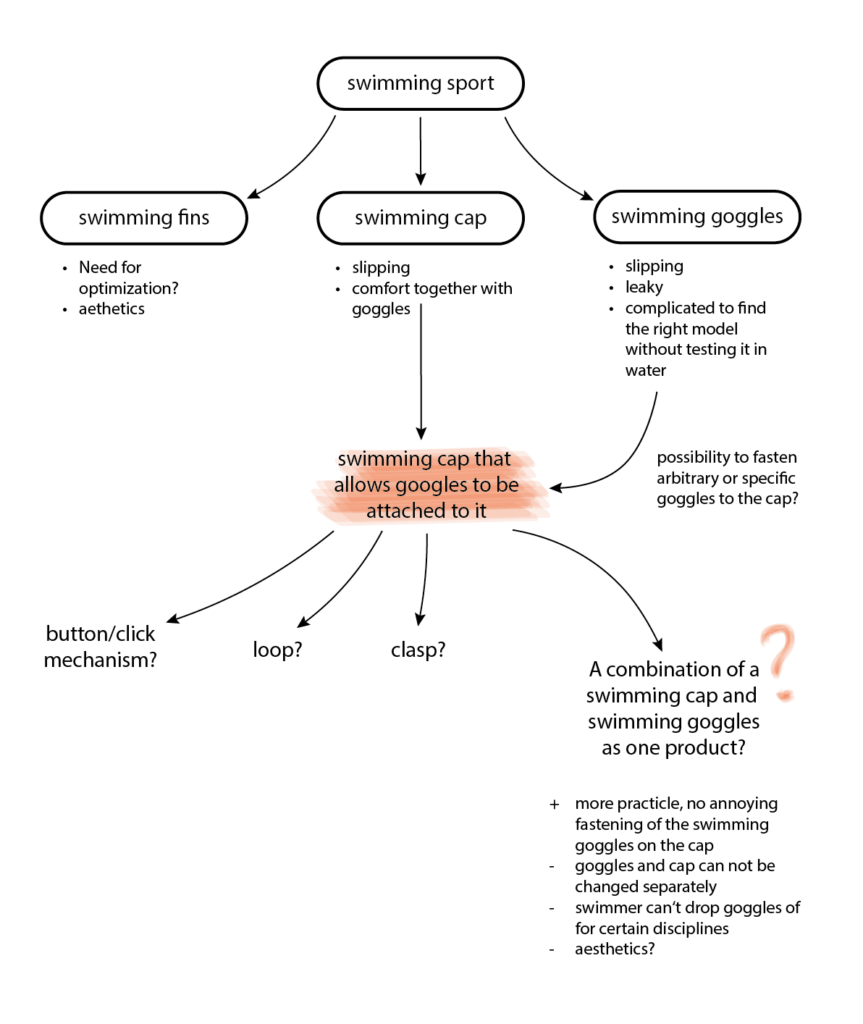

Analyzing the problem

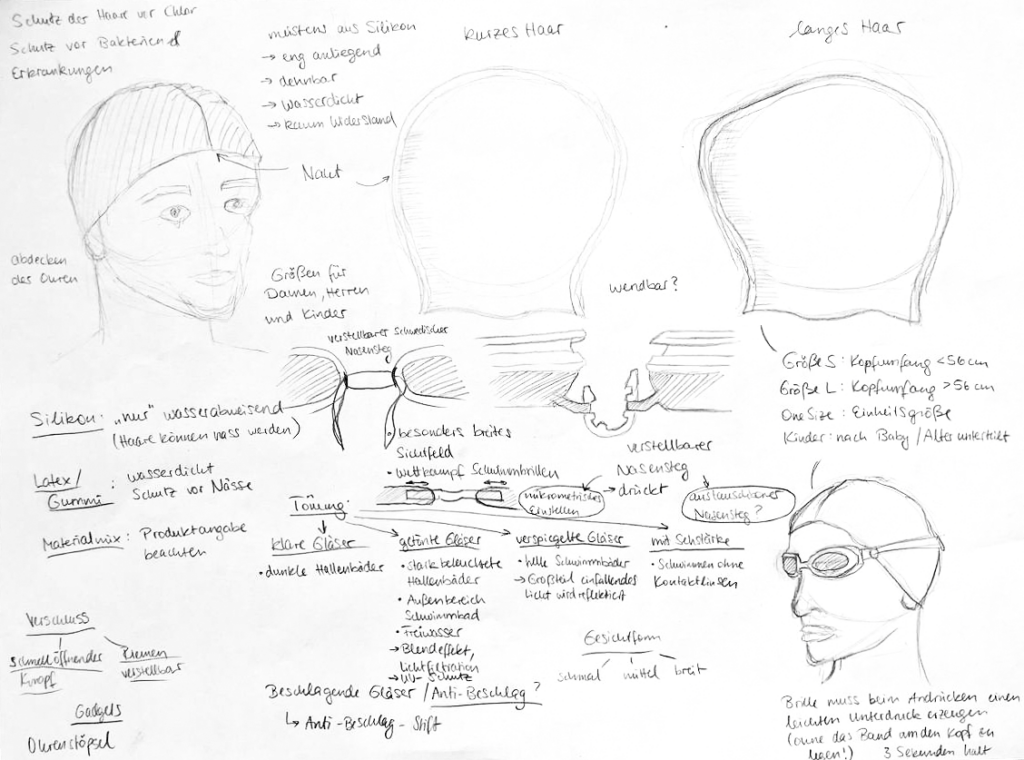

First of all, I did a research about the different kinds of swimming caps and goggles. It turned out that depending on the discipline, the type of swimming goggles can differ a lot. The same also holds for the swimming cap, where the size of your head and hair length are the relevant parameters.

Main Idea

I noticed that swimming caps are rarely worn by people doing water sports (except for professionals). The main reasons are:

- the silicon pulls on the hair,

- water gets trapped inside the ear and can’t flow out, and

- the cap is not comfortable to wear in combination with swimming goggles.

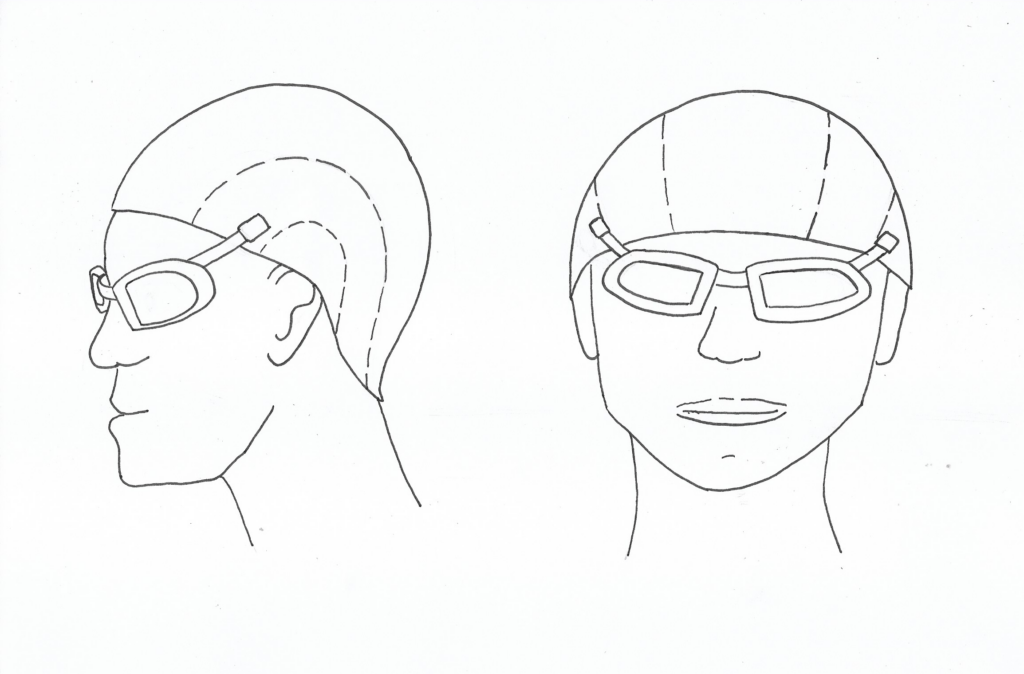

Due to my personal experiences as an advanced swimmer, I became aware of this serious issue. So I decided to challenge myself by redesigning the swimming cap. The main idea to overcome the problems mentioned above was to invent a mechanism that allows the user to easily fasten and unfasten the goggles directly to the cap.

First Model

I quickly started with the first model: To get a feeling for the material, I sewed my own swimming cap with green jersey fabric. Simultaneously, I tried an asymmetric sewing pattern which I crafted by my own as part of the new design. For the googles, I chose a classical round design.

The asymmetric cap did not fit as well as I thought. Also, the round design of the swimming glasses did look like the models that already existed.

New Functions

I decided that the overall product should consist of the cap and the goggles as two separate pieces: It should always be possible to remove the goggles.

To this end, I added these functions to my design:

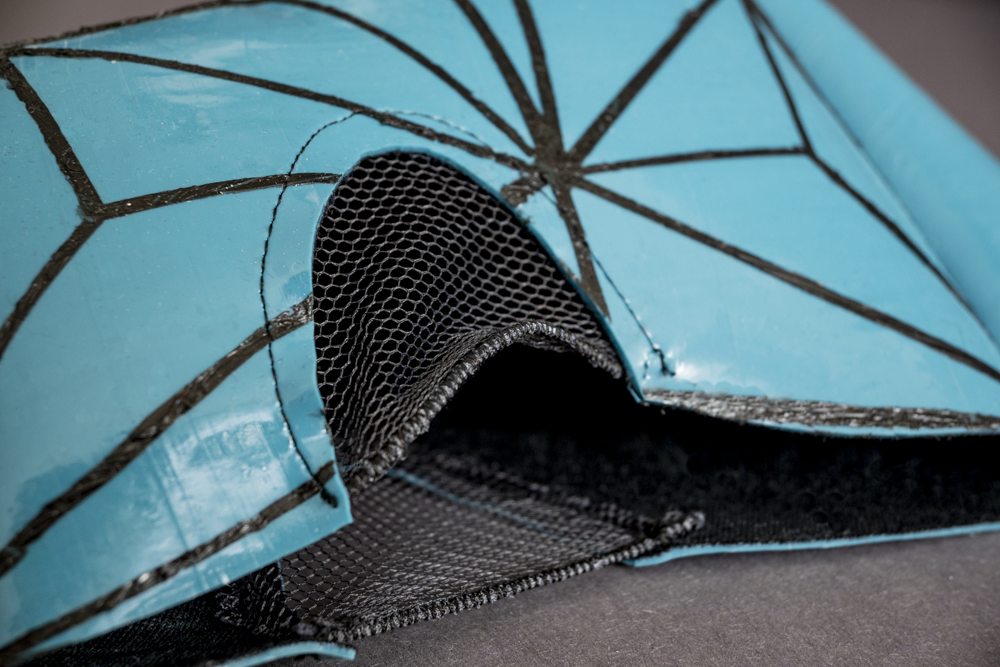

- For the cap, a hybrid material is used: The inside will be made out of polyester lycra blend to prevent the pulling on the hair. The outside will be made out of silicon for water resistance.

- The ear area will be cut out. This will allow water to drain from the ear.

- The goggles can be fastened by clasping them against the cap. Once they are in this position, tiny but strong magnets help to keep them in place. This mechanism also gives the product its name “ClipCap”. A similar approach is used by FIDLOCK, but with an additional button to unfasten the goggles.

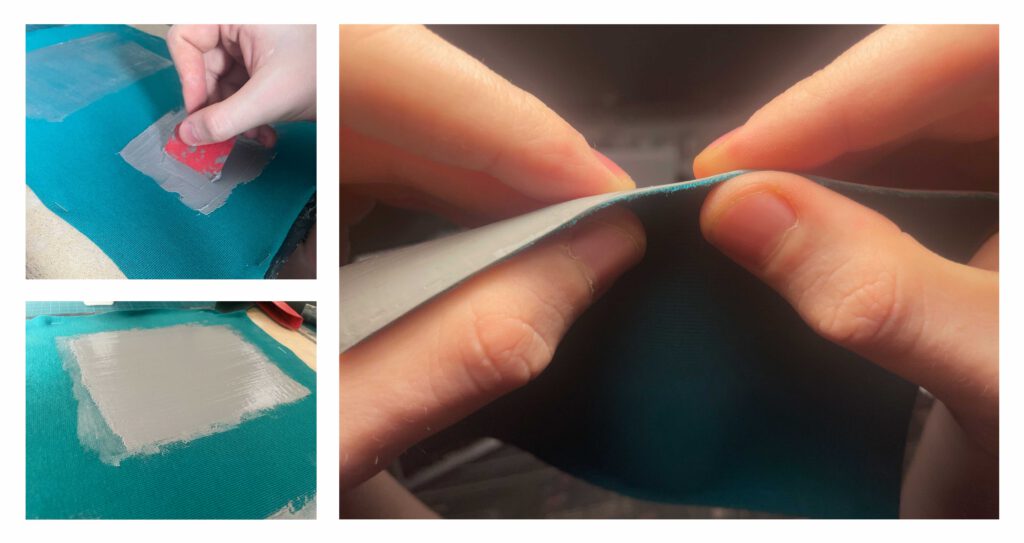

Material studies

For an authentic model, I wanted to see, if I can craft my imagined hybrid fabric. I tried to combine silicon with a jersey fabric. I added about 3 thin layers and then cut it out: it worked really well.

Second Model

Now, I tried to sew a swimming cap from the crafted hybrid material. I built a new symmetric sewing pattern and applied it on the material. The model turned out to be really robust and waterproof from the outside.

Swimming Goggles Prototype

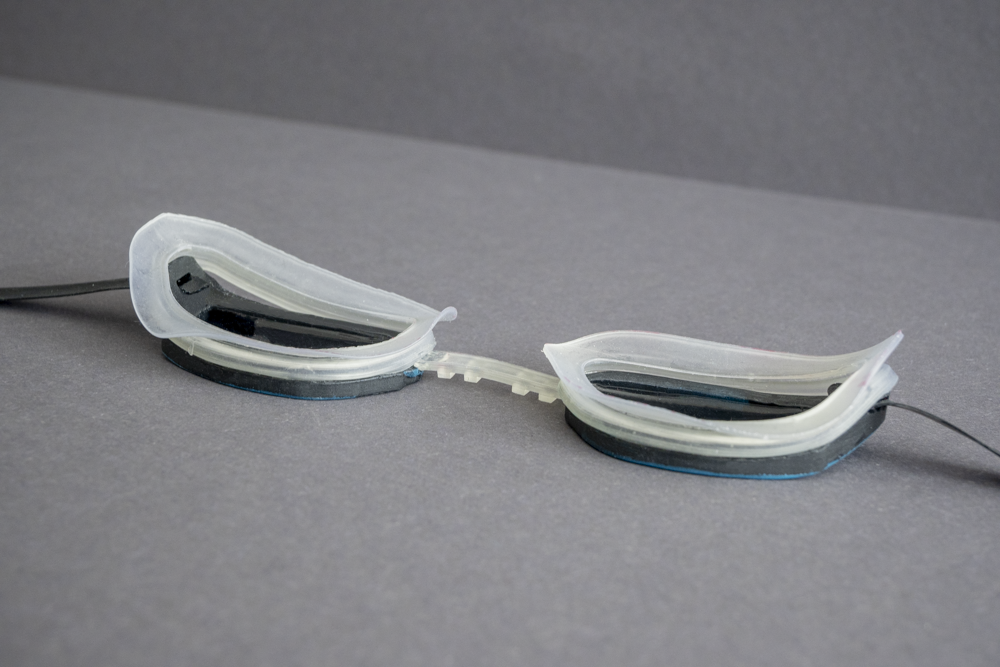

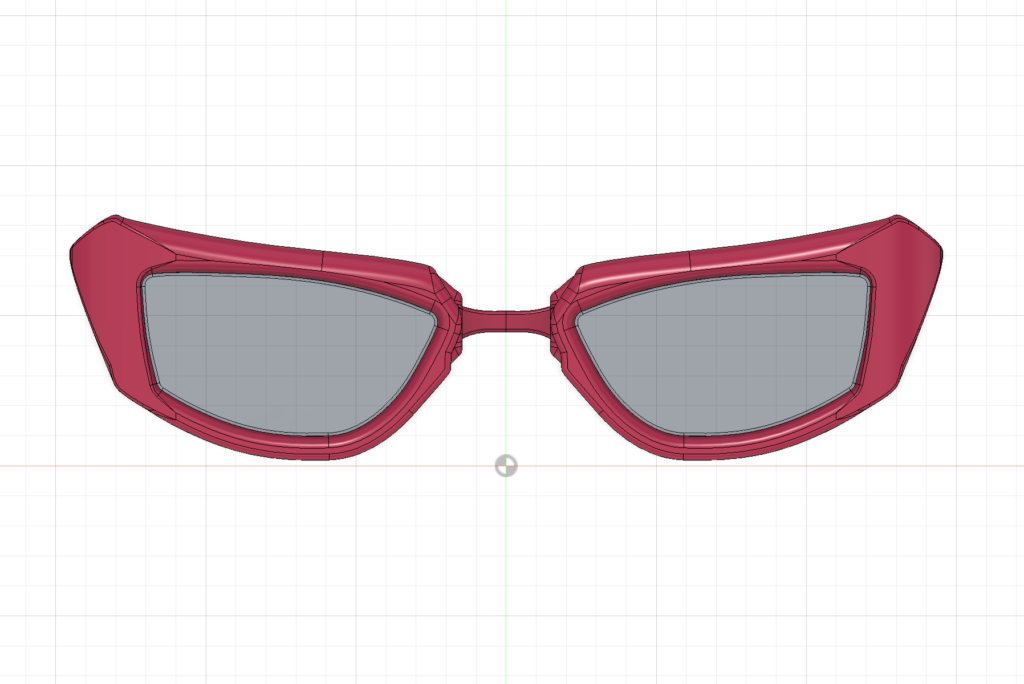

I decided to build the swimming googles through an SLA 3D printer. The first model was designed using Fusion 360.

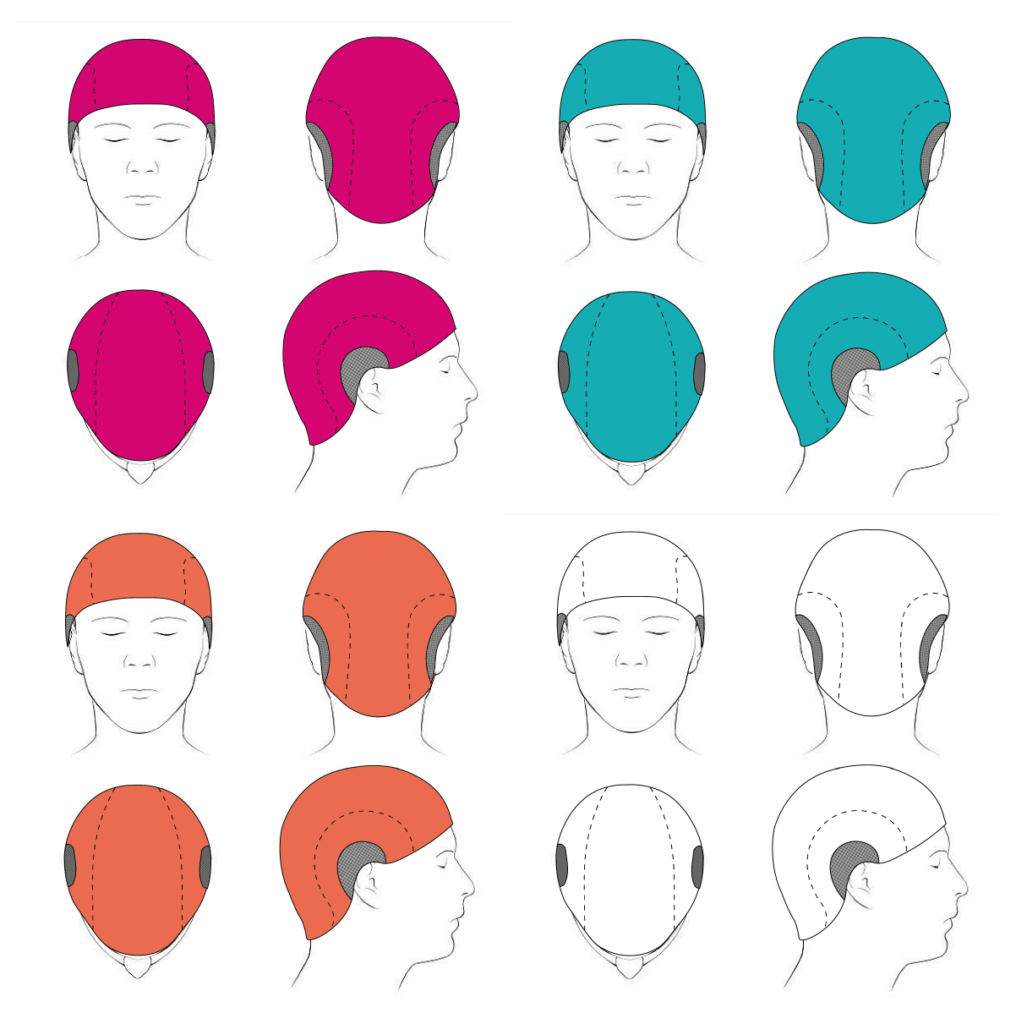

Colour Variations

I wanted an athletic, modern and non-old fashion look for my product. So, I decided to do color variations in 4 different vibrant colors shown on the left side. During this step, I decided to add a mesh fabric in the ear area for a tighter fit.

Refinement of the Swimming Goggles

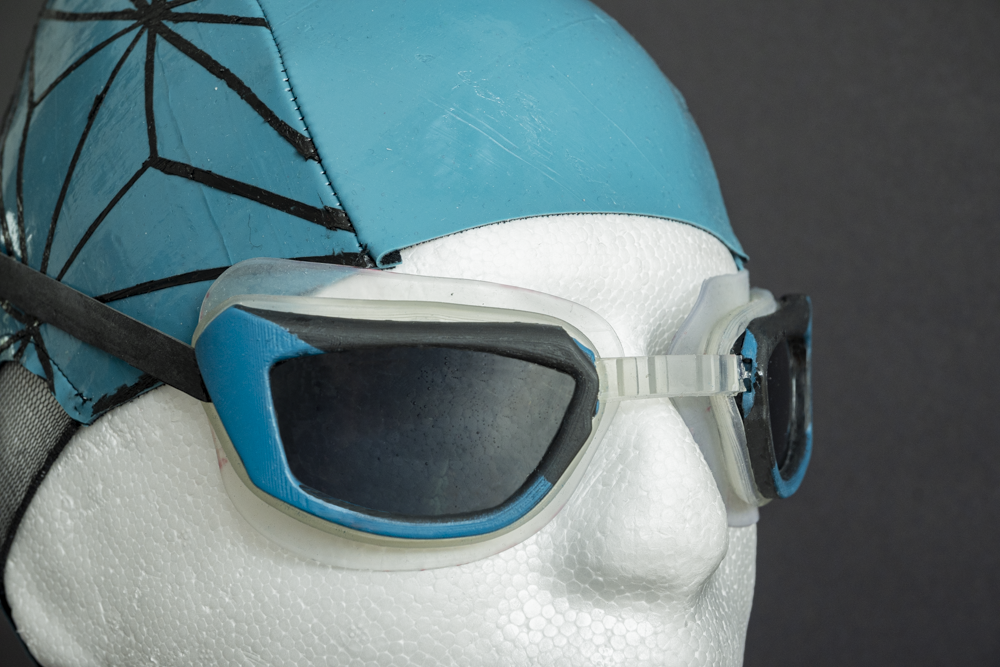

I wanted the swimming goggles to be coloured black in order to contrast with the swimming cap design. The belt is also made out of silicon and the clasp will be made out of plastic with the magnet inside.

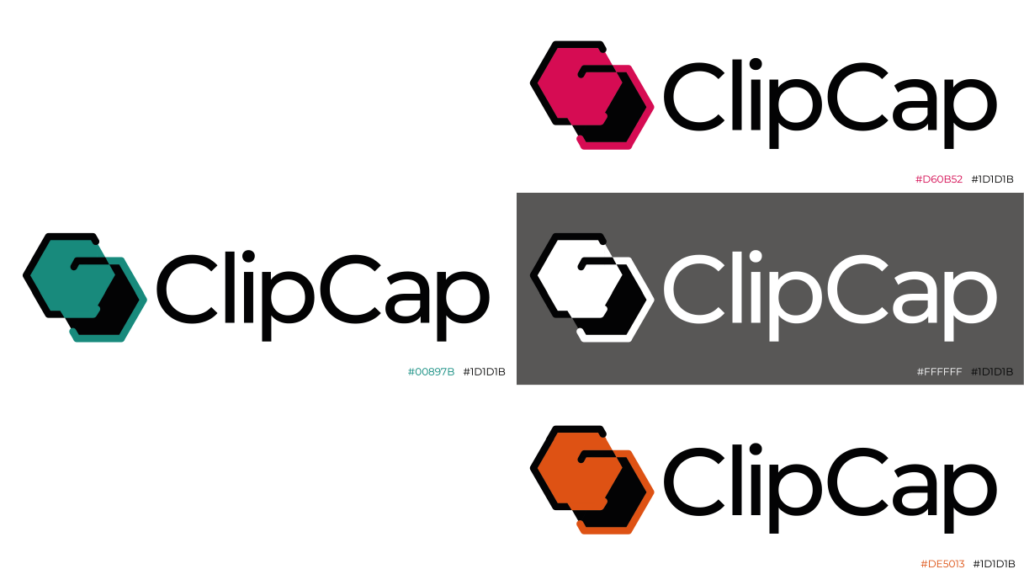

Logo and Product Name

The name “ClipCap” originated from the simple clasp mechanism. The logo mark resembles to the initial letters “C”. I chose Montserrat as logotype.

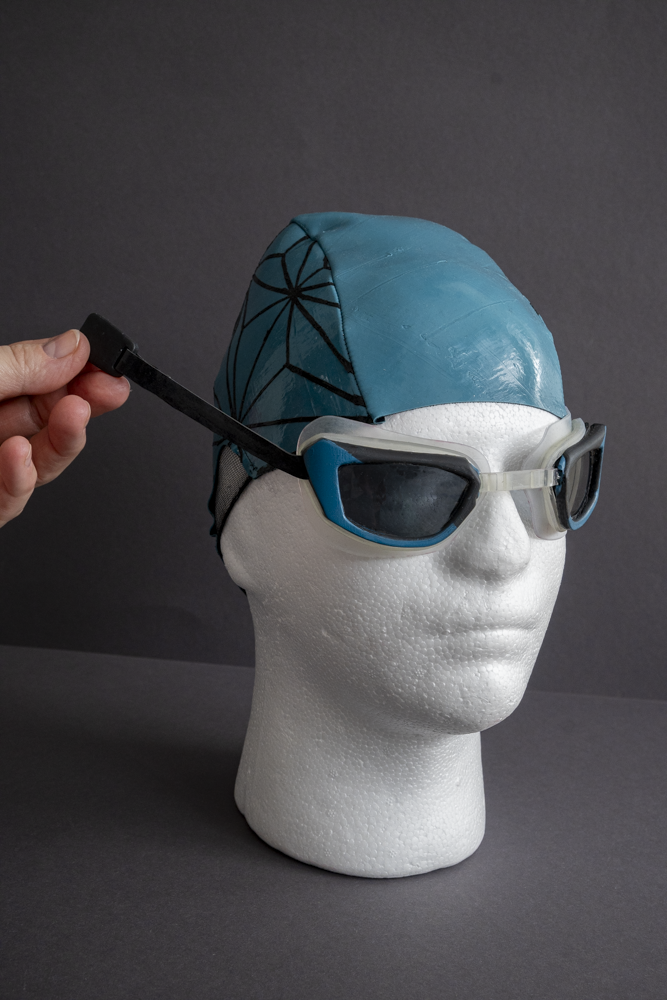

Prototype

The prototype was built the same way as the second model, but now the fabric mesh was added. Also, on the side areas I added a geometrical pattern matching the logo. The logo itself is printed on the backside. The goggle frames and the clasps were made out of black resin. For the sealing rings and nose bridge I used elastic resin with an SLA 3D printer.

Take a look further down for more details of the prototype. You can also take a look at a fictional proposal, project structure plan and documentation (only in German).