The topic of sustainability is playing an increasingly important role in many areas of everyday life. The use of disposable tableware in particular is a problem that has not yet been solved: In many situations (e.g. camping, catering, concerts, …) disposable tableware is often the only practical choice. Every year, around 370,000 tons of waste are generated from non-biodegradable disposable tableware – only in Germany (status 2017, ascending trend, source). One possible solution could be to use biodegradable materials.This has also been suggested in the past, e.g. to save plastic packaging. The aim of this project was to develop a disposable cup made from plant residues.

The Material

The first and most important step was the selection of a suitable material. We choose lucerne and mushroom substrate. These two materials proved well-suited in many ways: Both can be shaped and hardened well. They are also degradable natural products that are available in large quantities.

The Manufacturing Process

In order to obtain a malleable mass from the raw material, we experimented with different binding agents. It turned out that sufficient binding can be achieved by adding water and starch. In comparison, the mushroom substrate proved to be more resistant than lucerne, which is why we only used the mushroom substrate later on. We achieved the best results with a ratio of 50 g mushroom substrate: 50 ml water: 30 g starch.

In the final manufacturing process, the mass is pressed onto a negative mold and then burnt in the oven.

The material mixture was founded by the workshop manager, my fellow students and me. From now on, the design process was my own work.

Test Runs

Before the first prototype was created, the process was tested on a small scale. For this purpose, a glass marble was coated with the mushroom substrate mixture and baked out. The desired strength was achieved and the imprint of the marble was clearly visible.

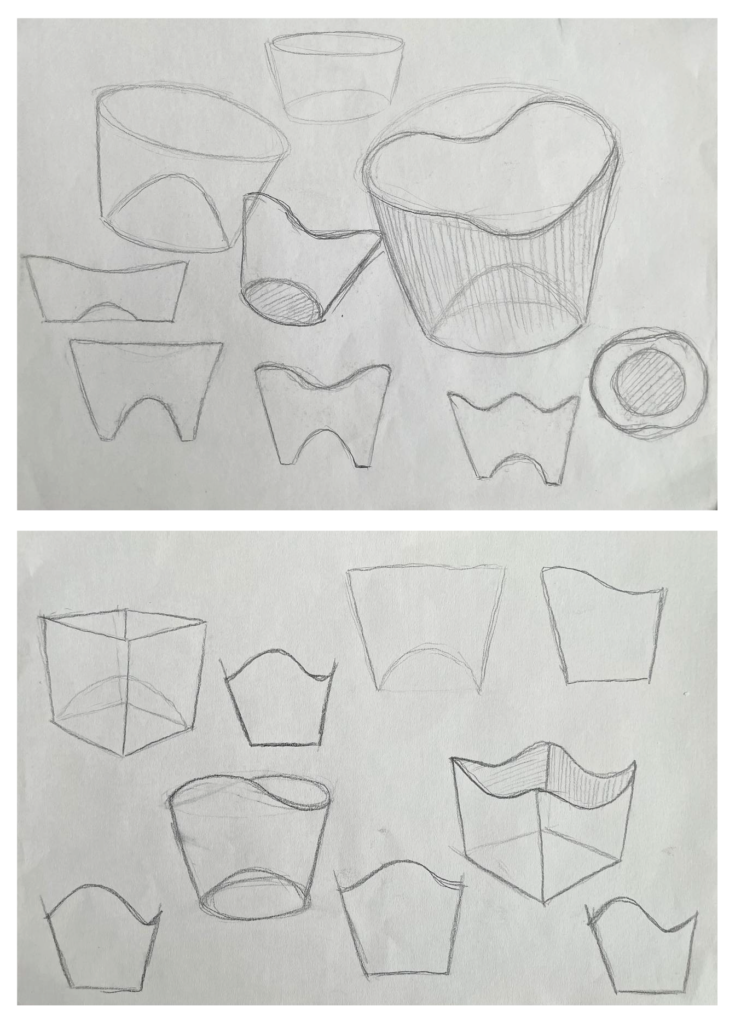

The Design

For the shape of the disposable tableware, I chose the shape of a cup. This can be used for many different kinds of foods, e.g. noodles, french fries, fruits, churros, and more.

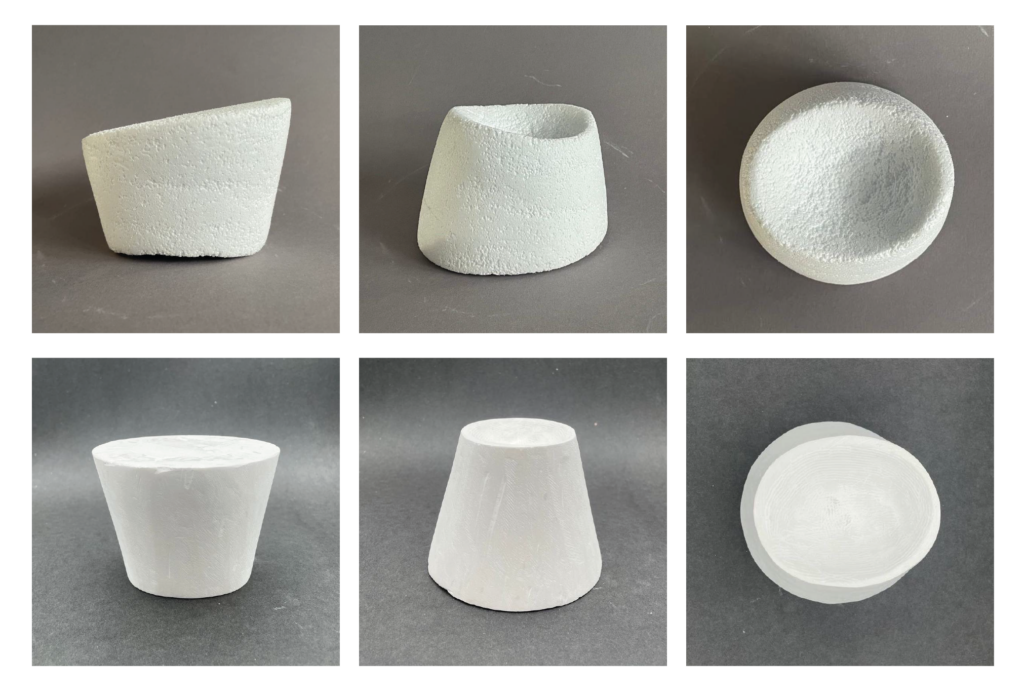

The cup has an oval base and widens upwards. For the cup rim, I experimented with different wavy shapes, but finally chose a smooth, beveled, circular edge because it was easier to make and more stable. The oval base makes the cup easier to hold in the hand. The circular edge forms a contrast to it. In addition, the base has a concave shape so that the food can disperse better within the cup.

Shaping the Form

Based on the draft, a model on scale 1:1 was made from styrofoam. This was then made in plaster. On this, the material will be formed and baked.

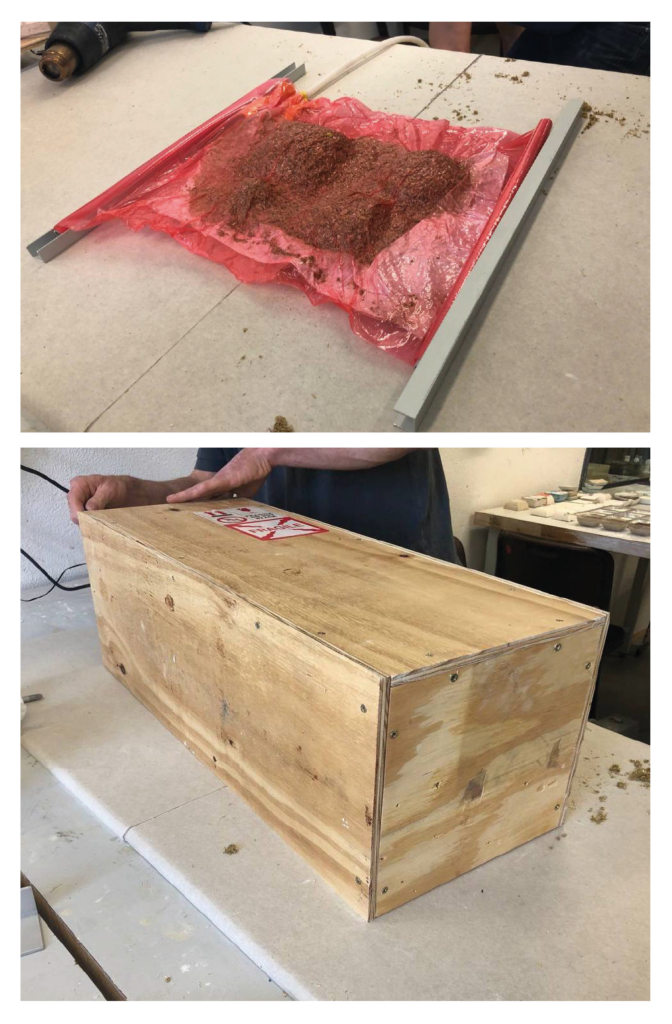

Preparation of the Baking Process

To ensure that the finished mug can be removed from the negative after baking, I coated the plaster mold with a mixture of soap, linseed oil and water. After mixing, the mushroom substrate mixture must rest for 30 minutes to absorb enough water. After that, I applied the mushroom substrate mixture to the negative.

The Baking Process

The prepared form was now wrapped in thermal foil and connected to a vacuum pump. This step ensures sufficient pressing and solidification of the material. Then, the form was baked in the oven, under this conditions:

- Start: 55° C / 131° F for 20 minutes

- Main: 90° C / 194° F for 20 minutes

- End: 120° C / 248° F for 30 minutes

After baking, I let my model cool down for about a week before separating the cup from the negative form.

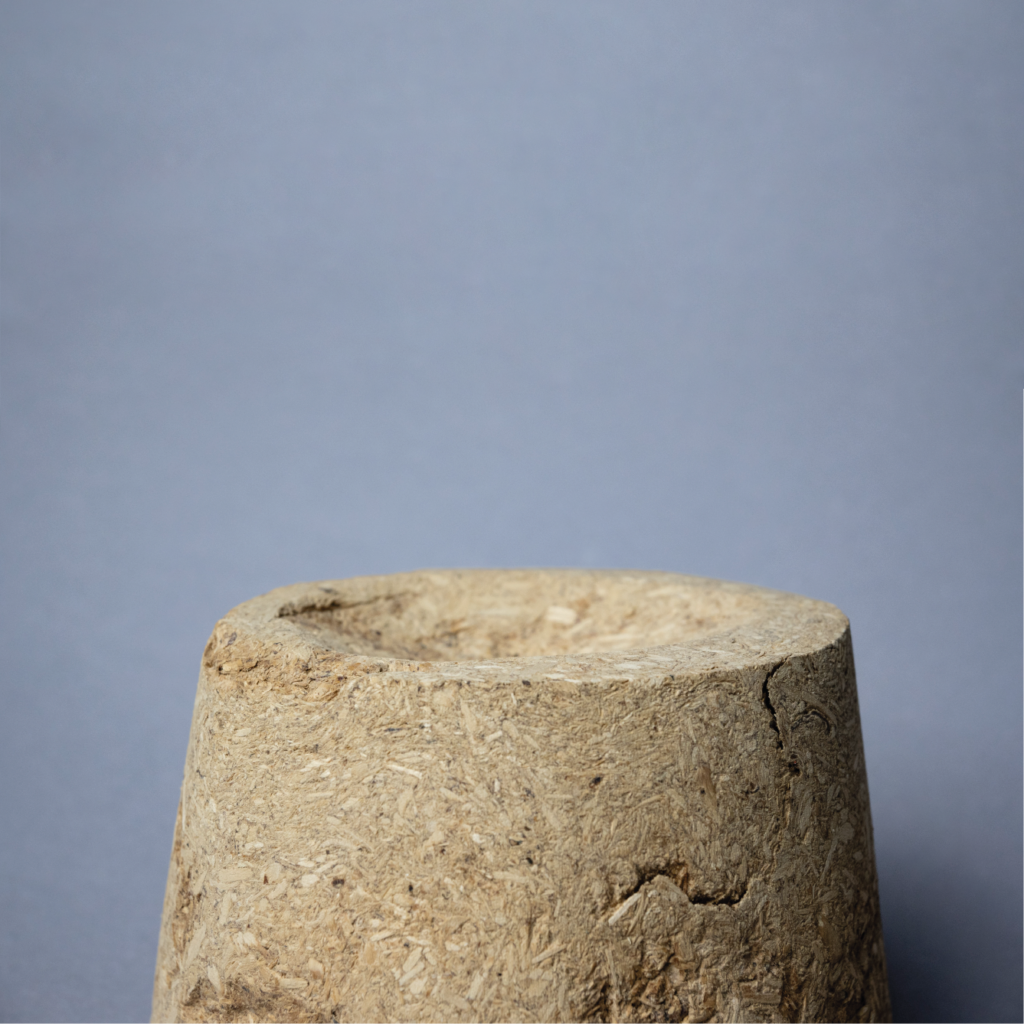

The Final Disposable Cup

The finished cup was then reworked with sandpaper to create a smoother surface.

I successfully tested the cup with some fruit, french fries and some bread.

The cup is currently not suitable for liquid foods. This would require a biodegradable coating, which is not currently available.

Take a look further down for more pictures of the finished model of the disposable cup.